Products

![]()

|

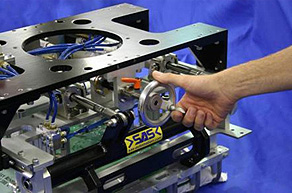

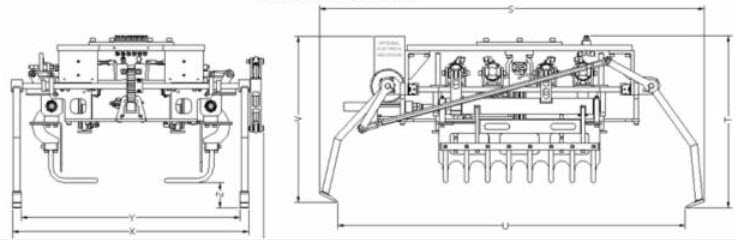

>SAS< Automation adjustable width bag gripper (ABG-25 & ABG-50) for palletizing plastic, woven cloth or paper bags. The ABG eliminates the need for costly, custom tooling with its unique width adjustment system. In less than 30 seconds, the tool’s bag width can be changed from 191-533 mm (7.5 to 21 inches).

Independent decking plates square-up and align the bag for precise placement on the pallet while the top mounted gripper plates maintain bag position on the ABG during robot travel to the pallet. Slip sheet and pallet hook options are available. |

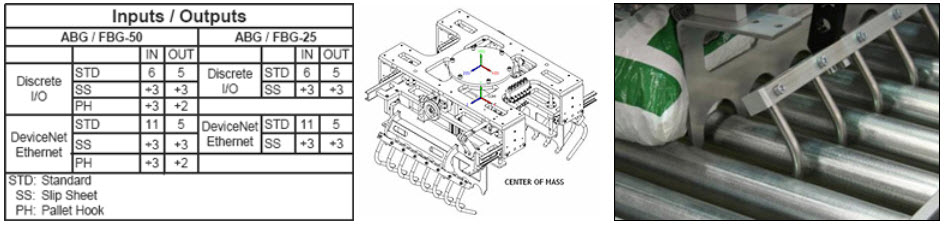

ABG / FBG 25/50

ABG / FBG 25/50 SS

ABG / FBG 25/50 PH

|

Standard ABG-25 components:

|

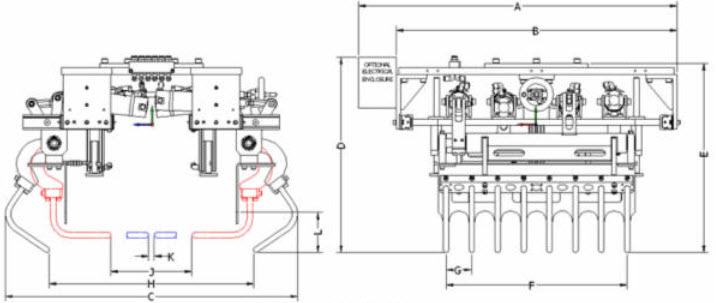

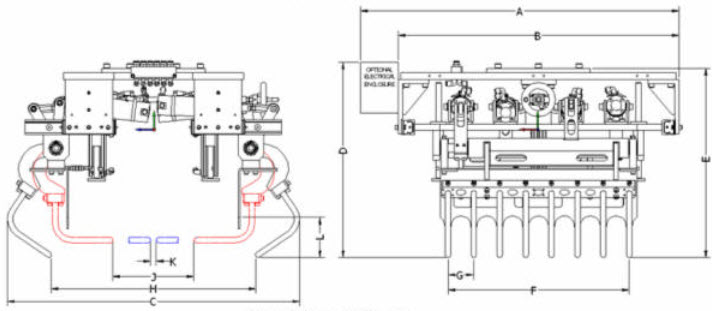

ABG - 25 |

|

| Slip Sheet option includes: | Compressed Air requirements: |

|

|

| Valve Package options: | |

|

Systems Integrators: Please call us for Integrator Pricing |

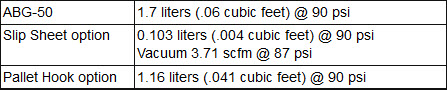

ABG-50 |

|

|

Standard ABG-50 components

|

| Pallet Hook option includes: | Compressed Air requirements |

|

|

| Valve Package options: | Slip Sheet option includes: |

|

|

|

Systems Integrators: Please call us for Integrator Pricing |

![]()